The increasing demand for efficient agricultural practices has led to the development of advanced production lines, particularly in bulk blending fertilizer. This innovation not only enhances productivity but also ensures that farmers receive high-quality products tailored to their specific needs. Understand the intricacies of such production lines is crucial for stakeholders aiming to optimize their operations.

Understand the Production Line for Bulk Blending Fertilizer

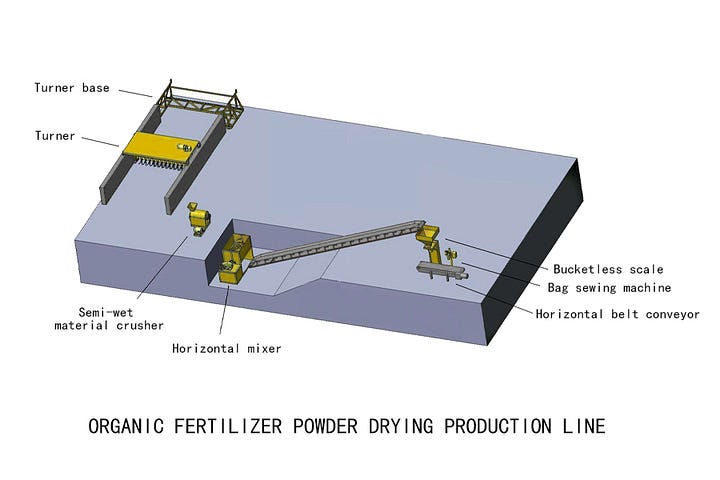

A production line dedicated to bulk blending fertilizer involves several key components designed to mix various raw materials effectively. These systems typically include storage silos, conveyor belts, and mixing equipment that work in unison to create customized blends based on soil requirements and crop types. The efficiency of this process significantly reduces labor costs while improving product consistency and quality. Moreover, automation within these lines allows for precise measurements and adjustments during production, catering specifically to market demands.

The Role of Granulator Machines in Fertilizer Production

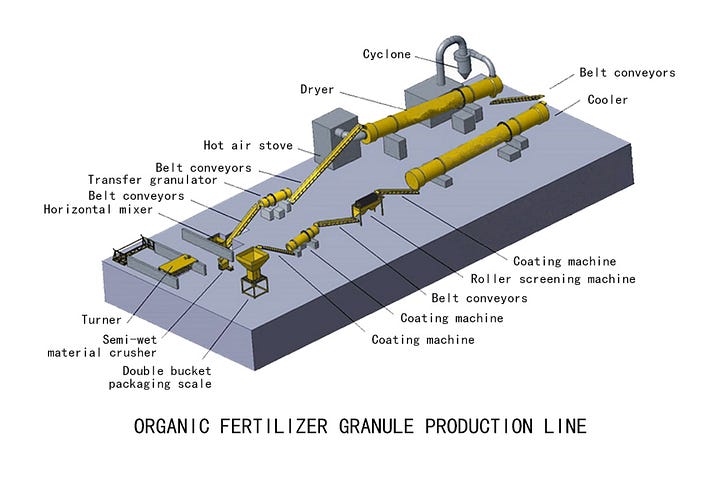

Granulator machines play a pivotal role in transforming blended fertilizers into granules suitable for application. By utilizing processes such as agglomeration or pelletization, these machines ensure that nutrients are evenly distributed throughout each granule, enhancing nutrient availability when applied to crops. Furthermore, modern granulators are equipped with technology that minimizes dust generation and improves overall handling characteristics of the final product. As a result, they contribute significantly not only to operational efficiency but also to environmental sustainability by reducing waste.

Find more about granulator machine for fertilizer.

Xincheng: A Leader in Fertilizer Production Solutions

Xincheng stands out as an industry leader specializing in comprehensive solutions for fertilizer production lines including bulk blending systems and granulation technologies. Their commitment to innovation is evident through their state-of-the-art machinery designed with user-friendly interfaces and energy-efficient operations. Xincheng’s expertise extends beyond manufacturing; they provide extensive support services ensuring clients can maximize productivity from installation through maintenance phases. This dedication positions them as a trusted partner within the agricultural sector.

Conclusion: The Future of Bulk Blending Fertilizers

The significance of a well-designed production line for bulk blending fertilizer cannot be overstated; it represents an essential component driving modern agriculture towards greater efficiency and sustainability. As we continue navigating challenges posed by climate change and food security concerns, investing in advanced technologies like those offered by companies such as Xincheng will be vital in meeting global agricultural demands effectively.