When it comes to industrial applications, especially in sectors like oil and gas, manufacturing, and infrastructure, the need for accurate pipe thickness measurement cannot be overstated. Pipes undergo wear and corrosion over time, leading to potential risks that can disrupt operations, reduce efficiency, and even result in catastrophic failures. This is why the use of reliable pipe thickness measuring instruments is essential for maintaining the structural integrity of piping systems. One of the most effective and widely adopted tools for this purpose is the ultrasonic thickness gauge, a technology that is revolutionising the way industries measure metal thickness.

Understanding Pipe Thickness Measurement

Pipe thickness measurement is critical for assessing the health of a pipeline. Over time, external factors like corrosion, erosion, and chemical reactions can thin the metal walls, which compromises the pipe’s ability to transport liquids or gases safely. By measuring the remaining wall thickness, maintenance teams can determine the risk of failure, perform timely repairs, and extend the life of pipes without disrupting operations.

Pipe thickness measurement helps prevent catastrophic failures by detecting areas where the pipe may be weakened. This allows for early intervention to replace or repair sections of pipe before they fail, significantly reducing downtime and repair costs. The two most common methods used for measuring pipe thickness are destructive and non-destructive testing methods. The non-destructive approach, which includes ultrasonic testing, is preferred in most industries because it doesn’t harm the material being tested.

Why Ultrasonic Thickness Gauges are the Best Choice

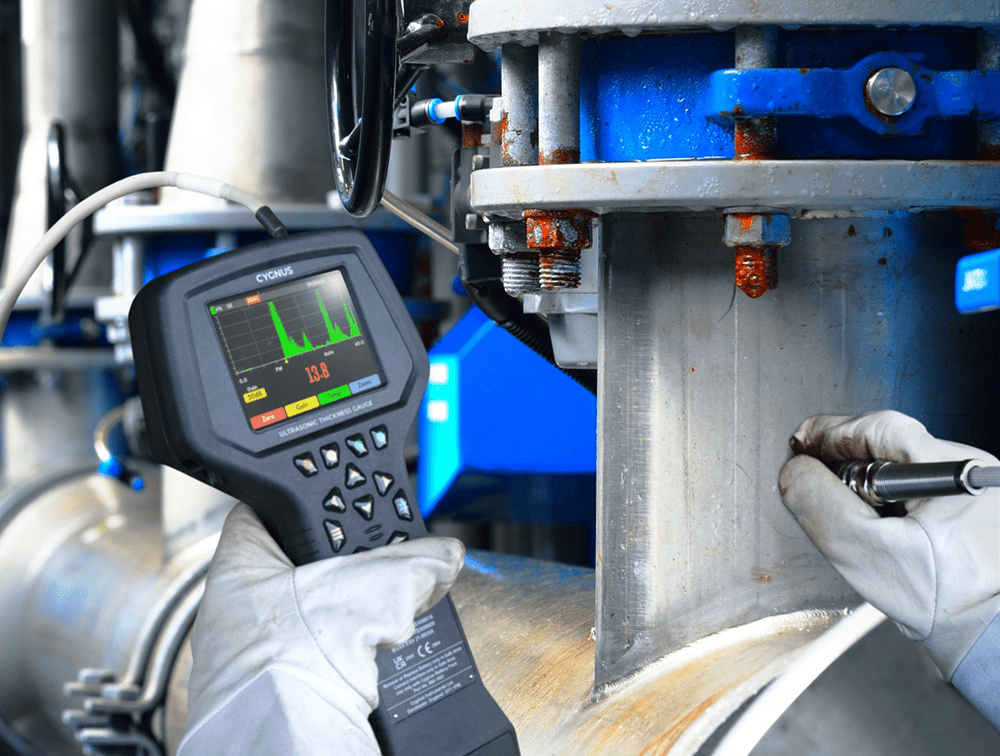

Ultrasonic thickness gauges are widely regarded as one of the most reliable and effective pipe thickness measuring instruments available. These devices work by emitting high-frequency sound waves from a transducer, which then travel through the material. When the sound waves encounter a boundary between materials, they are reflected back to the transducer, and the time it takes for the wave to return is used to calculate the thickness of the material.

Advantages of Ultrasonic Thickness Gauges:

- Non-destructive: As a non-invasive method, ultrasonic testing ensures that no damage is done to the pipe during measurement, making it the preferred choice for assessing the integrity of pipelines and equipment.

- High accuracy: These instruments can provide highly accurate readings, even for pipes with coatings, rust, or other surface irregularities. They are capable of measuring thickness down to millimetre precision.

- Versatility: Ultrasonic thickness gauges can be used on a wide range of metals, including steel, aluminium, copper, and more. This makes them versatile tools for industries that rely on different materials for their pipes and infrastructure.

- Portability and ease of use: Modern ultrasonic thickness gauges are compact, lightweight, and easy to use, allowing technicians to perform on-site inspections with minimal disruption to operations. The results can be obtained quickly and can be instantly recorded or transferred to other systems for further analysis.

Cygnus Instruments: Leading the Way in Pipe Thickness Measurement

Cygnus Instruments is a name synonymous with precision, reliability, and innovation in the field of ultrasonic thickness measurement. As a leader in the development of ultrasonic thickness gauges, Cygnus has been at the forefront of providing industries with tools that enhance safety, streamline maintenance processes, and ultimately save costs.

With decades of experience in producing cutting-edge pipe thickness measuring instruments, Cygnus Instruments has earned a reputation for manufacturing highly accurate and durable ultrasonic thickness gauges. These tools are designed to withstand harsh environments, providing consistent and precise readings in both laboratory settings and challenging field conditions.

Key Features of Cygnus Ultrasonic Thickness Gauges:

- High Performance in Harsh Environments: Cygnus Instruments’ ultrasonic gauges are engineered to perform in extreme conditions, from offshore oil rigs to manufacturing plants with high temperatures, moisture, or vibration.

- Advanced Technology: Cygnus integrates advanced technology into its devices to ensure reliable performance. Some models feature multi-frequency capabilities, allowing users to measure a range of thicknesses on various materials without compromising accuracy.

- User-Friendly Interface: Designed with user-friendliness in mind, Cygnus ultrasonic gauges have intuitive interfaces that allow for quick calibration and easy operation. Technicians can rapidly assess pipe thickness and determine areas of concern without extensive training.

- Data Logging and Reporting: Many of Cygnus’ ultrasonic thickness gauges come with data logging features, allowing users to store measurements for future reference. This helps in building a comprehensive history of inspections, assisting in long-term maintenance planning.

How to Measure Metal Thickness with Ultrasonic Devices

Measuring metal thickness using an ultrasonic gauge is straightforward, but requires a bit of knowledge to ensure the results are reliable. Here’s a quick step-by-step guide to using an ultrasonic thickness gauge effectively:

- Preparation: Ensure the surface of the pipe is clean and free from dirt, rust, or other debris that could affect the accuracy of the measurements. If necessary, clean the surface with a wire brush or abrasive pad.

- Calibration: Before beginning measurements, calibrate the ultrasonic thickness gauge to ensure accuracy. This usually involves measuring a test block of known thickness to verify the gauge’s accuracy.

- Application of Coupling Gel: To transmit sound waves effectively between the transducer and the pipe, apply a coupling gel to the surface of the pipe. This gel ensures the sound waves can travel through the metal without interference.

- Taking Measurements: Place the transducer on the pipe surface and activate the gauge. The device will send sound waves into the metal and measure the time it takes for the waves to return. The thickness reading will then be displayed on the screen.

- Repeat for Multiple Points: To get an accurate assessment of the pipe’s overall condition, take measurements at multiple points along the length of the pipe. This will help detect any areas with significant wear or thinning.

- Recording Results: Save or record the results for future reference. Many ultrasonic thickness gauges, including those from Cygnus Instruments, come with built-in data storage or can connect to software for further analysis.

Conclusion

In industries where pipe integrity is critical, using precise pipe thickness measuring instruments like ultrasonic thickness gauges is essential. Cygnus Instruments has become a trusted name for providing high-quality, accurate, and durable ultrasonic gauges that help businesses monitor and maintain the structural health of their pipelines and metal structures. With the ability to measure metal thickness accurately, easily, and non-destructively, these instruments offer a reliable solution to prevent costly failures and improve the efficiency of maintenance operations.

By investing in the right technology, companies can extend the lifespan of their assets, ensure compliance with safety standards, and avoid downtime—ultimately leading to significant cost savings and improved operational performance.