Cold storage facilities are a key enabler of industries that need temperature controlled storage and include food production, medicine and agriculture industries. These intricate structures have very stringent requirements for thermal characteristics of the building construction materials with accompanying demands for strength and durability coupled with relatively low cost. This is where PUF panels (Polyurethane Foam panels) comes into picture as a revolutionary panel. Because of the superlative performance and energy efficient capability of these practical and versatile panels, those employed in the construction of cold storage are fast becoming a favorite substitute for conventional building materials such as tin.

PUF panels consist of a foam core of polyurethane surrounded by outer skins of attached metal or other material, usually pre-coated. This structure provides an outstanding thermal break and hence it makes them suitable for cold storage applications. Compared to the conventional tin structures that allow heat transfer and hence temperature differences, the PUF panels regulate interior temperatures of the stored goods hence extending their shelf life.

It is important in construction of cold storages or clean rooms to maintain environment since the storing of perishable goods requires low temperatures to reduce spoilage. While this may seem positives in and out, the most important aspect where the PUF panels play a role is in conserving energy. Again, due to their relatively light weight it is easier to install these types of building materials as compared to conventional materials that may sometimes require reinforcement. Thirdly, PUF panels possess high durability, which makes them capable to resist to the severe environment conditions, as well as, being protected against pestilence, moisture and chemical influences, which are important for cold storage companies.

Since they provide a way improved insulation, strength, and installation, PUF panels have revolutionized construction of cold storage units. Due to the ever increasing focus on business operations and improving cost effectiveness, the requirement of PUF panels for constructing cold storage is steadily increasing. Pronto, a well-known manufacturer of PUF panel, is right now leading this change throughout the country and offer premium services to cope with the modern integrated cold storage unit.

Superior Insulation: The Key to Efficient Cold Storage

However, insulating is one of the essentials of coping with cold storage facilities for efficient cooling. These are basically chambers which serve principally to regulation of internal temperature in the huge capacities: no matter what the weather outside, these storages, must be kept at a constant temperature. This is important for companies such as agricultural and pharmaceuticals and food sectors where the products are required to be stored under certain temperature. In this regard, PUF panels (Polyurethane Foam panels) have proved to be one of the best insulating products that make cold storages work optimally.

Hence, the ability of cold storage panels to insulate depends with the manner in which it was manufactured. The sandwich rigid polyurethane foam acts as a strong thermo barrier and much heat is opaque between the interior and exterior of a storage unit. While tin structured building lets a good amount of heat into a room and require extra time in trying to regulate the temperature of the room, PUF panels ensure little fluctuation of the temperatures. This capacity to sustain steady internal conditions is perhaps particularly important for refrigeration, as well as protection of perishable goods from spoilage, and for the safety of products that are preserved in cold storage facilities.

Another important characteristic is indicated by the figures of thermal conductivity of PUF panels that are low. This property makes them much better than conductors like tin which as been stated, cannot efficiently deter the exchange of heat. Steady-state techniques are frequently not adequate for structures constructed from tin as additional school insulation layers may need to be added to provide even fundamental thermal performance, which likewise ends up boosting construction time, cost of construction and running inefficiency. On the other hand, the PUF panels incorporate insulation as a part of the panel body, leaving no room for other layers and offering top-class cold storage.

It must also be appreciated that superior insulation yields considerable energy savings. Compared to other facilities, the cooling system in cold storage using PUF panels requires less effort to achieve the optimal temperatures. So this entails lower energy usage which in turn means lower bills for electricity and impacts the environment with a lesser number. In the longer run, PUF panels make longer economic sense when it comes to constructing cold storages because of the sustainable power saving that the panels afford.

Especially for industries that require very accurate temperatures for their product storage, the effectiveness of cold storage is heavily influenced by insulation. This study also shows that by installing PUF panels businesses can get maximum performance, safeguard their products and keep operating expenses low. Having supplied the best quality PUF panels to a numerous clients, Pronto aims to offer optimum solutions to the users that help them establish efficient cold storage facilities in their business organizations.

Energy Savings With PUF Panels

Due to the characteristics of cold storage facilities, energy efficiency it is one of the most important aspects to consider when constructing or managing this type of facility. These structures involve the use of several temperatures to store perishable products, consequently resulting in high power usage. The use of PUF panels in the construction of cold storage assets makes it possible for the business to significantly decrease power consumption and minimize expenses without affecting power.

The use of cold storage wall panels also effectively reduce insulation and this has a direct relationship to energy utilization. The members are made of a rigid polyurethane foam core that effectively insulates the cold storage unit by reducing heat transfer across the walls between the inside and outside environment. This makes the interior to be more stable in terms of temperature, with little variation, this hence lays less demand on the cooling systems. On the other hand, the traditional materials such as tin offers poor thermal performance hence more heat is gained within the facility. This means that cooling systems have to operated, thus using much energy and consequently inflating electricity costs.

The energy-saving resource of cold storage panels is manifold by the fact that they retain their R-value rating for a long time. While structures made of tin erode with time and with constant usage becomes non insulated, PUF panels remain effective for years. This durability of the energy savings makes it quite possible to offer business owners and managers a worthwhile solution to their operations costs.

In addition to what as mentioned above, it could also mentioned the compatibility of PUF panels with sophisticated temperature control systems. Due to such insulation efficiency, there is much that business organizations can do to enhance the cooling systems for maximum energy conservation. For instance, cooling units that can work at low rates for a long time instead of the implementation of a short ON and OFF cycles that are both wasteful of energy and faster the deterioration of that equipment.

Besides the matter of the far lower costs of PUF panels, the decrease in energy consumption also benefits the global environment. That will minimize the use of energy hence reducing the emission of greenhouse gases making PUF panel the best option for cold storage construction. As will be observed below, this is a great advantage, especially for companies that want to enhance their sustainability by adhering to green building standards.

For this reason, by using PUF panels in its construction the cold storage businesses can save a lot of energy in addition to increasing the efficiency of their business. When it comes to PUF panels, Pronto is a market leader that always comes up with solutions related to cold storage needs, thus guaranteeing costs savings while addressing environmental concerns as well.

Comparison: PUF Panels vs. Tin and RCC Structures

When constructing cold storage facilities, choosing the right material is crucial to ensure efficiency, durability, and cost-effectiveness. Among the commonly used materials, PUF panels, tin structures, and RCC (Reinforced Cement Concrete) constructions are often considered. However, cold storage PUF panels clearly outperform tin sheet and RCC in terms of thermal insulation, energy efficiency, installation speed, and overall cost-effectiveness, making them the superior choice for modern cold storage solutions.

PUF Panels vs. Tin Structures

Even though tin is cheap and easily obtained it does not possess the heat retention required for cold conservation. Tin structures offer high conductance and hence allow for heat conduction possibly creating the need for adding extra layers of insulation that will enable this environment provide cold storage. All these extra layers add cost and complexity to construction of the building and do not come close in efficiency to PUF panels.

On the other hand, the PUF panels have insulation incorporated into it because of its rigid polyurethane foam central framework. Because the cladding performs well in this area, this cuts out the need for additional insulating, which also reduces cost and construction complexity. Also, it was noted that over time tin structures develop problems like corrosion, condensation, wear and tear than PUF panels that are resistant to moisture as well as exhibit relatively unchanged thermal performances for several decades.

PUF Panels vs. RCC Structures

Cold storage construction using RCC structures may be considered as a durable structure for construction, but there are some shortcomings associated with them. The construction of RCC building take a longer time to complete and troop huge quantity of manpower, material and time. Besides, insulation in RCC cold storages is not entirely efficient; it is compulsory to add further insulation to polystyrene or foams, which makes construction lengthy and costly.

In contrast, PUF panels are manufactured off-site, which are then transported and have to be erected on site. This leads to a drastically shorter construction period, less manpower demands and shorter overall time to complete a construction project. They are also thin and rigid making it easy to handle and install hence speeding up the construction process as compared to RCC construction which consumes plenty of time due to the heavy nature of RCC construction.

From a cost point of view, structures of RCC are much costlier if the added cost of insulation, extra and longer construction work and annual general maintenance charges are considered. Being an integral part of structure construction, PUF panels are characterized by lower installation and mainainence costs and demonstrate multifold financial benefits in the long run with energy efficiency and need for refurbishment.

The Clear Winner: PUF Panels

When comparing PUF panels with tin and RCC structures, the advantages of PUF panels are clear. They provide:

- Superior thermal insulation for consistent temperature regulation.

- Faster construction timelines due to their prefabricated design.

- Lower overall costs, both during construction and in long-term operation.

- Enhanced durability and resistance to moisture, pests, and wear.

By opting for PUF panels, businesses can construct cold storage facilities that are energy-efficient, cost-effective, and built to last. As a trusted name in PUF panel manufacturing, Pronto is committed to delivering cutting-edge solutions that outperform traditional construction methods, setting a new standard for cold storage excellence.

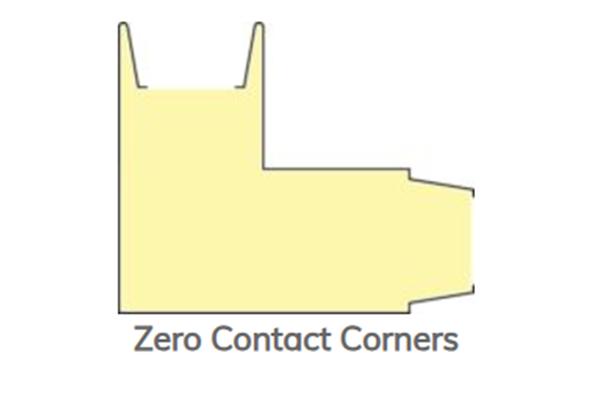

Zero Contact Panels: A Revolutionary Change in Cold Storage Construction

A new add on in the field of cold storage construction is the Zero Contact Panel by Pronto. This panel comes as a casing which not completely overlaps and seals off the gap at intersection of two panels, but also provides insulating cover at the corners of a building. This creates an air tight space which greatly increases the energy savings for a cold storage as almost no air is able to escape to the outdoors.

This means increased efficiency and great cost savings which are not possible to achieve in RCC and tin based storages as air is always leaking out from the corners of these structures. These Panels thus also make them an obvious choice for applications like Clean Rooms, Pharmaceutical Manufacturing and industries which require high level of sanitation and isolation from external environment as well.

Durability and Longevity of PUF Panels

Longevity is particularly important in the construction of cold stores, because they are relatively large investments that need to be made to withstand harsh climate. PUF panels further improve in this respect as they provide better strength with even better resistance to externals than that of tin or RCC (Reinforced Cement Concrete). This makes cold storages that are constructed using PUF panels to have durability as a key attribute and thus guarantee value for money throughout the useful life of the building elements.

The main material used in the construction of PUF panels, rigid polyurethane foam, is not only the best insulator, but also very long-lasting. It is then clad in between two stiff outer skins, mostly of pre-coated galvanized steel or aluminium. This construction contributes to mechanical stability of PUF panels which remain in their given shape and function under pressure. Tin constitutes are, however, pressed easily and can easily dent or twist and some of them rust which makes them require frequent replacement and thus are more costly to maintain.

Another great advantage of the PUF panels is its durability and effectiveness in cases of moist and humid conditions. Cold storage wall panels are generally exposed to conditions that facilitate formation of condensation. In their turn, tin and RCC-based panels are notorious for problems like rust stains, mold and water damage, which does not affect PUF panels. This is apart from affirming the durability of the cold storage unit itself as well as serving the cleanliness standards needed in such industries such as the food processing and the pharmaceutical one.

Where PUF panels really excel is in its ability to withstand varying temperatures and the adverse working environment. Common to RCC structures is the cracking that results from thermal movements over time compromising on insulation and maintenance costs. Tin structures, however, are not very strong, and, therefore, may degrade rapidly when used in extreme conditions. Temperature and physical stability makes the PUF panels ideal for the cold storage sector as they do not degrade with fluctuations in temperature.

Moreover, the PUF panels are also not affected by pests, especially in cold storages where the main aim is to avoid contamination. While RCC and tin may accumulate dust and often provide suitable breeding ground for pests it is important to maintain, PUF panels provide a pest proof barrier.

Due to this fact, PUF panels are more economical than its counterparts because of its long life expectancy. Although the cost of acquisition may be relatively high compared to tin, the low levels of maintenance and better performance resulting in low costs in the long run. In addition, they tend to be significantly more energy efficient, and less costly in terms of maintenance over RCC structures, making it a wiser choice for the sophisticated cold storage of today.

Due to their impressive durability and resistance to challenges in an environment, PUF panels are laying new strong foundations for building cold storage. As a manufacturer of PUF panels, Pronto produces competitively that meet high quality and the performance, durability and reliability that may benefit businesses in managing and safeguarding their investments in the highly challenging and competitive industries of the present. Owing to these features, it becomes an obvious choice for clean room panels as well.

Ease of Installation and Maintenance

Building a cold storage facility requires precision, efficiency, and minimal disruption to operations. Materials that simplify the construction process without compromising on quality or performance are essential. PUF panels stand out as a game-changing solution, offering unparalleled ease of installation and low maintenance requirements compared to traditional options like tin and RCC (Reinforced Cement Concrete). These benefits make PUF panels a preferred choice for businesses looking to streamline cold storage construction and operation.

Quick and Hassle-Free Installation

PUF panels are preformed off site and brought in and fixed on site. On the same note, it affords on-site construction time due to the fact that; A) layering insulation B) applying coatings and C) curing of concrete, are some of the complicated processes that are required in RCC and tin-based structures are avoided. The panels have means for engagement that allow for a snap-on installation that guarantees a tightly encased system which is important in preservation of cold temperature within the cold storages.

However, construction of RCC cold storage facility is more time consuming and labor intensive than steel because it involves more of preparations and handling of materials, as well as curing time. Tin structures would take slightly lesser time to be constructed than RCC structures because additional insulation layers would have to be applied. PUF panels eliminate these challenges in its entirety, and can construct cold storages without any compromise on the structure strength and insulation.

Minimal Maintenance Requirements

One of the primary assets of, or benefits associated with, PUF panels is the ability to have a low maintenance. Therefore, the exterior and interior skin and the rigid polyurethane foam core, has additives that make it resistant to wear and tear, moisture, pest or corrosive agents. This is especially so for cold storage businesses, as they are located in areas with tough conditions where items such as tin and RCC deteriorate.

For instance, structures developed from ‘tin’ can be vulnerable to corrosion and rust and this is made worse by high humidity and this would always call for periodical examinations, fixing and replacement. RCC structures durable though requires to undergo surface crack, thermal breakout and structural deterioration at regular interval, which are very expense to be repaired and made good. PUF panels are made to be durable and to keep up efficiency and aesthetics without integral care.

The surface of the PUF panels is smooth and features non-porous nature, which makes cleaning a breeze; an important factor when storing perishable such as food items, pharmaceuticals among others. It also makes them very suitable to uphold high hygiene standards because they do not support the growth of mold, mildew or bacteria.

Cost-Effectiveness of Easy Installation and Low Maintenance

The ease of installation and reduced maintenance requirements of PUF panels translate directly into cost savings. Faster construction timelines reduce labor costs and project delays, while the minimal need for repairs and replacements lowers long-term operational expenses. Compared to RCC and tin, where ongoing maintenance can quickly add up, PUF panels offer a much more cost-effective solution for cold storage construction or for use as clean room panels in laboratories or pharmaceutical industry.

A Streamlined Solution for Modern Needs

By combining fast installation with long-lasting performance, PUF panels provide a streamlined approach to building and maintaining cold storage facilities. Businesses can benefit from reduced downtime, quicker project completion, and fewer operational disruptions—all while ensuring that their facilities meet the highest standards of efficiency and durability.

Pronto, a trusted manufacturer of PUF panels, is dedicated to providing innovative solutions tailored to the unique demands of cold storage construction. With PUF panels, businesses can enjoy the advantages of modern construction technology, delivering efficient, durable, and easy-to-maintain cold storage solutions that stand the test of time.

Eco-Friendly and Sustainable Construction

In today’s world, sustainability is a growing priority across industries, including cold storage construction. Businesses are increasingly seeking materials and solutions that minimize environmental impact while maintaining high performance and cost-effectiveness. PUF panels (Polyurethane Foam panels) offer a sustainable alternative to traditional materials like tin and RCC (Reinforced Cement Concrete), making them an ideal choice for modern cold storage facilities.

Energy Efficiency and Reduced Carbon Footprint

There are different kind of contribution of PUF panel towards sustainable development one of them is energy efficient. The fire rating of PUF panels also makes it easier for structures to reduce heat transfer as the panels offer better insulation. This results into reduced energy usage and therefore leads into reduced utilization of greenhouse gases. On the other hand, tin constructions are not good insulators, meaning that more energy is needed to regulate the temperatures in cold storage hence high electricity consumption and the consequent extra carbon footprint.

Although RCC structures are more strong and require less maintenance, it has been found that they do not insulate as effectively as the required temperature without additional layers of insulation thus requiring more energy and materials than the other three options. Businesses will be able to provide energy efficiency and in turn help create a clean and green environment than when they had to use metal panels.

Lightweight and Resource-Efficient Construction

Due to the construction of panels that makes up PUF, it is lighter than RCC and largely in precast hence needs minimal raw materials and manufacturing energy as is the case with RCC. It also cuts the amount of emissions from the site during construction hence minimizing the effects on weather conditions. Also, their portability reduces the costs associated with handling, transportation, and erection since compact structures require little energy to move and set up.

It is impervious, light in weight but is less durable and more of it has to be replaced or repaired frequently thus being a high waste material in the long run. RCC construction involves the use of a great number of resources which include cement, and aggregate, water and steel reinforcement. Energy cost of these materials and curing as well as insulation costs places RCC as a less environmental friendly compared to the PUF panels.

Recyclability and Longevity

PUF panels are useful for years and in some cases for decades without requiring much attention and interference. Such durability however work to decrease the rate of replacement hence minimizing waste production throughout the lifecycle of the cold storage facility. Further, the use of components that are recyclable makes many PUF panels, meaning that material can be reused after their service, thus not adding to landfill.

On the other hand, tin structures dissolve rather rapidly and are often discarded and replaced frequently, although RCC structures are very durable and can take a longer span before being considered for disposal the major problem is that RCC structures being composite in nature and incorporating a lot of weight in their structures, cannot be recycled easily.

Compliance with Green Building Standards

PUF panels are increasingly being recognized as a sustainable building material that aligns with global green building standards. Their energy efficiency, recyclability, and minimal environmental impact make them an attractive choice for businesses aiming to achieve certifications like LEED (Leadership in Energy and Environmental Design). Cold storages constructed with PUF panels not only provide operational efficiency but also help businesses meet sustainability goals and regulatory requirements.

A Smarter, Greener Choice

By choosing PUF panels for cold storage construction, businesses can significantly reduce their environmental impact while reaping the benefits of energy efficiency and cost savings. Their eco-friendly properties, combined with superior performance and durability, make PUF panels a forward-thinking solution for the challenges of modern cold storage construction.

Pronto, as a leading manufacturer of PUF panels, is committed to promoting sustainable construction practices by providing innovative and environmentally responsible products. With Pronto’s PUF panels, businesses can create cold storages that are not only efficient and durable but also contribute to a healthier planet.

Conclusion: A Smarter Choice for Modern Cold Storage

Cold storage construction demands materials that can meet the rigorous requirements of thermal efficiency, durability, and cost-effectiveness. As the backbone of industries such as food processing, agriculture, and pharmaceuticals, these facilities must maintain consistent internal temperatures while minimizing energy consumption and operational costs. PUF panels (Polyurethane Foam panels) have emerged as the ideal solution, surpassing traditional materials like tin and RCC (Reinforced Cement Concrete) in every critical aspect.

Revolutionizing Cold Storage with PUF Panels

PUF panels bring together cutting-edge insulation technology, robust structural properties, and an eco-friendly design to create cold storage facilities that are efficient and reliable. Their superior thermal insulation ensures stable interior temperatures, reducing the workload on cooling systems and leading to significant energy savings. Unlike tin, which struggles to prevent heat transfer, or RCC, which requires additional insulating layers, PUF panels integrate insulation directly into their structure, providing a seamless, high-performance solution.

Their prefabricated design allows for faster and more efficient installation compared to RCC, which involves lengthy construction timelines, and tin, which often requires supplementary materials for insulation. Additionally, PUF panels are lightweight and easy to handle, reducing construction complexity and labor costs.

A Long-Term Investment in Efficiency and Sustainability

One of the standout features of PUF panels is their durability and longevity. Resistant to moisture, pests, and environmental wear, they outperform both tin and RCC in terms of maintenance and lifecycle costs. The minimal upkeep required by PUF panels translates into lower long-term operational expenses, while their recyclability and energy efficiency make them a sustainable choice for environmentally conscious businesses.

The energy savings achieved by PUF panels are particularly notable. By reducing the cooling system’s energy consumption, they not only cut electricity bills but also align with global sustainability goals by minimizing carbon emissions. These advantages make PUF panels an investment that pays off over time, both financially and environmentally.

Pronto: Leading the Way in Cold Storage Solutions

As a trusted manufacturer of high-quality PUF panels, Pronto is at the forefront of transforming cold storage construction. Pronto’s PUF panels are designed to meet the unique demands of cold storage facilities, delivering unmatched thermal performance, durability, and ease of installation. By choosing Pronto, businesses can build state-of-the-art cold storages that meet modern efficiency standards while staying ahead in a competitive market.

The Clear Choice for Cold Storage Excellence

Whether you’re constructing a new cold storage facility or upgrading an existing one, PUF panels are the smarter, more cost-effective, and sustainable choice. They offer a comprehensive solution that addresses the challenges of traditional materials while paving the way for modern, efficient, and eco-friendly cold storage construction.

Pronto’s innovative PUF panels represent the future of cold storage, combining performance, reliability, and sustainability in one package. For businesses seeking to enhance their operations, reduce costs, and support environmental goals, PUF panels are undoubtedly the way forward.